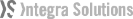

The adoption of filterpress technology is a strategic solution for dewatering tailings from mining processes, precisely meeting the critical need of our customers:

- Achievement of a high level of dewatering

- Water recycling in the plant process

- Reductions in environmental risks and impact on surrounding areas and community

- Disposal area optimization and footprint reduction

- Extension of mine life

One of the main challenges we face at Diemme in managing these projects is achieving the specific target moisture required by the customer. The process begins in our laboratory, where we conduct rigorous tests on the supplied sludge samples, aiming to perfect the dewatering process. The result is a cake of optimal dryness, allowing safe, efficient storage with minimal environmental impact.